Dorsey Metrology

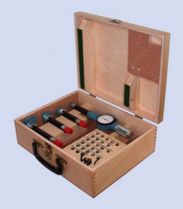

Dorsey Dial Bore Gage Combination Kit

DORSEY1BOREGAGECOMBINATIONKIT

Industry’s most popular dial bore gage now available in an easy-to-use combination kit

.

Dorsey Dial Bore Gage Setmasters

DORSEYDBMSETMASTERS

Bore gages are comparator type instruments used to compare parts being manufactured (unknown sizes) to known dimensions. “Setting” the bore gage to a known dimension requires the use of a reference master. The master ring is the most common type reference master used in industry and each ring is limited to one specific hole size. This means that a master ring inventory can reflect a large investment. Dorsey’s adjustable bore gage setmasters maintain all the advantages of master rings, but provide the added feature of adjustability. Within the specified capacity of each Dorsey “Setmaster”, any dimension can be set by easily adjusting the master to a preset combination of gage blocks.

.

Dorsey DYN Groove Gage

DORSEYDYNGROOVEGAGE

Dorsey's Dynamike Model DYN groove gage combines a patented ball bushing slide with a series of gaging arms to suit almost any application. Gaging contact retraction is accomplished by using a conveniently mounted thumb lever while gaging range adjustment is accomplished by sliding the static gaging arm along its precision ground rail.

.

Dorsey DYS Groove Gage

DORSEYDYSGROOVEGAGE

Dorsey's Dynamike Model DYS groove gage combines a light weight, compact rigid cast frame and a patented ball bushing slide with a series of interchangeable gaging arms to suit virtually any application.

.

Dorsey LDA Series

DORSEYLDASERIES

Dorsey’s most popular series of ID/OD gage uses rigid steel tubing, cast end blocks, and a precision right angle transfer mechanism similar to our bore gages which gives accurate and sensitive readings.

.

Dorsey LDAR Midget Reed Gage

DORSEYLDARMIDGETREED

This economical, heavy duty production gage features a rigid steel plate frame and our bullet proof reed spring gaging transfer. The LDAR mechanism is impervious to coolants, dirt, and contaminants and offers great repeatability.

.

Dorsey LDAR Series

DORSEYLDARSERIES

LDAR gages feature a lightweight tubular steel frame with a reed pantograph movement. The pantograph movement utilizes parallel springs to transfer motion and is well suited to production applications as dust, dirt or coolant cannot harm or jam the mechanism.

.

Dorsey Model J2 Horizontal Jaw Gage

DORSEYJ2HORIZONTALJAWGAGE

The model J2 jaw gage features Dorsey’s proven precision lapped chrome/steel bushing in a rigid cast iron frame. A series of interchangeable contacts, and adjustable two axis rest stage along with a micrometer tail stock combine to make the J2 jaw gage suitable for most high accuracy OD inspection tasks.

.

Dorsey SSG Style Snap Gages

DORSEYSSGSNAPGAGE

This design of rugged production line snap gages has been the industry standard for more than 50 years. Dorsey offers this easily adjusted gage built to the same exacting specifications and precision as the original Standard Gage® product. Interchangeable repair parts for Standard Gage® products are also available.

.