Dorsey Metrology

Dorsey DYS Groove Gage

DORSEYDYSGROOVEGAGE

Dorsey's Dynamike Model DYS groove gage combines a light weight, compact rigid cast frame and a patented ball bushing slide with a series of interchangeable gaging arms to suit virtually any application.

.

Dorsey DYN Groove Gage

DORSEYDYNGROOVEGAGE

Dorsey's Dynamike Model DYN groove gage combines a patented ball bushing slide with a series of gaging arms to suit almost any application. Gaging contact retraction is accomplished by using a conveniently mounted thumb lever while gaging range adjustment is accomplished by sliding the static gaging arm along its precision ground rail.

.

Dorsey Dial Bore Gage Setmasters

DORSEYDBMSETMASTERS

Bore gages are comparator type instruments used to compare parts being manufactured (unknown sizes) to known dimensions. “Setting” the bore gage to a known dimension requires the use of a reference master. The master ring is the most common type reference master used in industry and each ring is limited to one specific hole size. This means that a master ring inventory can reflect a large investment. Dorsey’s adjustable bore gage setmasters maintain all the advantages of master rings, but provide the added feature of adjustability. Within the specified capacity of each Dorsey “Setmaster”, any dimension can be set by easily adjusting the master to a preset combination of gage blocks.

.

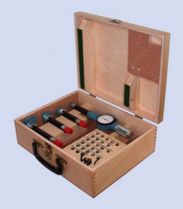

Dorsey Dial Bore Gage Combination Kit

DORSEY1BOREGAGECOMBINATIONKIT

Industry’s most popular dial bore gage now available in an easy-to-use combination kit

.

Dorsey Chamfer Gages

DORSEYCHAMFERGAGES

Dorsey Chamfer and Countersink Gages, for both Internal and External Chamfers and Countersinks.

.

Dorsey BC Universal ID/OD Bench Comparator

DORSEYBCIDODBENCHCOMPATOR

ADJUSTABLE INSIDE / OUTSIDE DIAMETER FIXTURES

This comparator offers 2 or 3 point measurements for both ID and OD on one benchtop plate. Features include two or three point measurement, linear ball bushing movement and a wide range of adjustment. The fixture can be positioned at any angle from horizontal to vertical to duplicate the machining process angle eliminating deflection and deformation variation as potential sources of error. Hardened steel work surfaces insures years of accurate trouble free use.

.